Igor Matteo Carraretto

PhD thesis title: Experimental characterization of air-water foamy flows

Academic Tutor: Luigi Pietro Maria Colombo

Academic Supervisor: Luigi Pietro Maria Colombo

PhD cycle: 34° (see all student profiles of the same cycle > LINK)

BSc: Energy Engineering, Politecnico di Milano

MSc: Energy Engineering, Politecnico di Milano

Non-Newtonian Fluid Dynamics Group at Mechanical Engineering Department (Massachusetts Institute of Technology, Cambridge, United States) with Professor Gareth H McKinley from September 2019 to April 2020

Roberto Rocca Doctoral Fellowship assigned by MIT and Fondazione Fratelli Agostino ed Enrico Rocca / Best Paper Award HEFAT 2019 / Leonardo Maugeri Doctoral Scholarship assigned by Maugeri Foundation and Eni SpA / Eni Scholarship assigned by Eni SpA

Thesis abstract

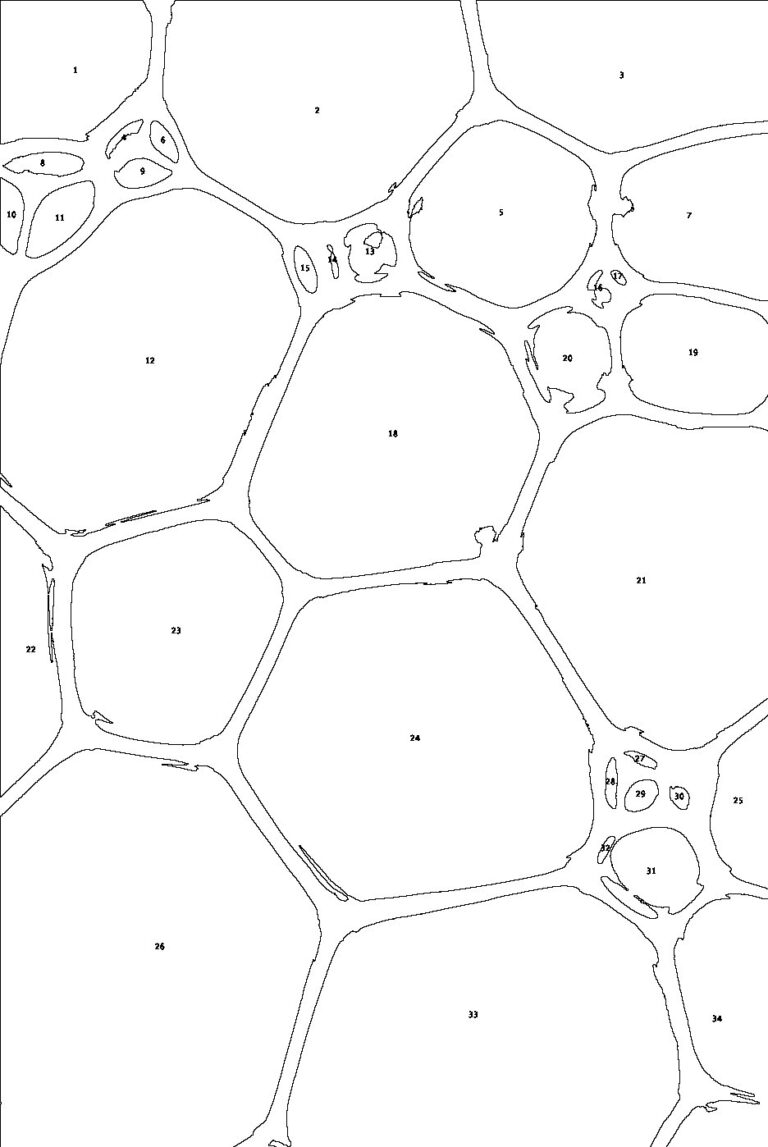

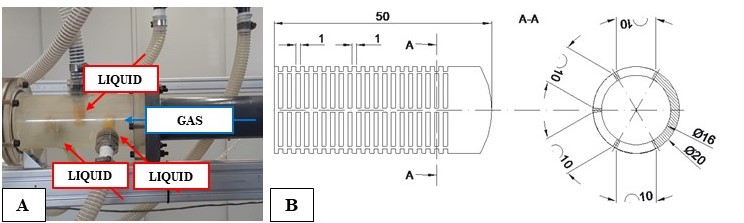

This work, carried out in the laboratory of Multiphase Thermal-Fluid Dynamics at Energy Department of Politecnico di Milano, presents the results of two experimental campaigns aiming at the characterization of a two-phase air-water flow in a horizontal pipe in the presence of surfactants, with the consequent generation of foam. Specifically, flow patterns, pressure drop and void fraction have been experimentally measured and analyzed. Two inner pipeline diameters were chosen to conduct the analysis ID = 30 mm and ID = 60 mm, having superficial gas velocities ranging from 2.67 to 8.17 m/s and 0.41 to 2.31 m/s respectively. First, air-water flow without surfactant was investigated: pressure drop and liquid holdup were measured to set the reference frame of the work. The results were compared against models reported in the open literature. With respect to the ID = 60 mm configuration both the Taitel and Dukler and the Ullmann and Brauner models failed in predicting pressure drop and liquid holdup at low gas superficial velocity, therefore the experimental results were used to obtain an empirical correlation for the interfacial shear stress. Then after the reference frame was set, air-water-foam flows were investigated: two main flow patterns were observed: plug flow at low gas velocity, stratified-wavy at higher velocity. Foam quality, pressure drop and void fraction were measured in the whole considered range. An optical probe was developed and subsequently upgraded to measure the liquid height variation. Eventually, the flow conditions were simulated with OLGA® software. The foam rheological properties, determined in a previous campaign, have been considered through the Herschel-Bulkley model with the yield stress varying through time due to foam decay. The results show good agreement of the uniform velocity profile and static foam properties at t = 0 s for the ID = 60 mm pipeline setup, with a pressure drop overestimation of 28.98 %; on the other hand the pressure gradient relative to the ID = 30 mm pipeline is well predicted when considering the linear velocity profile and foam properties at t = 2000 s from the generation, with a pressure drop overestimation of 4.78%.

Personal interest in my research theme

I find the study in my research topic very stimulating and challenging, in the sense that optimizing a process through a new technique which has been so poorly studied is very interesting as no one knows where it is headed to.